WAXMAX 5000 injector

Technology condensed

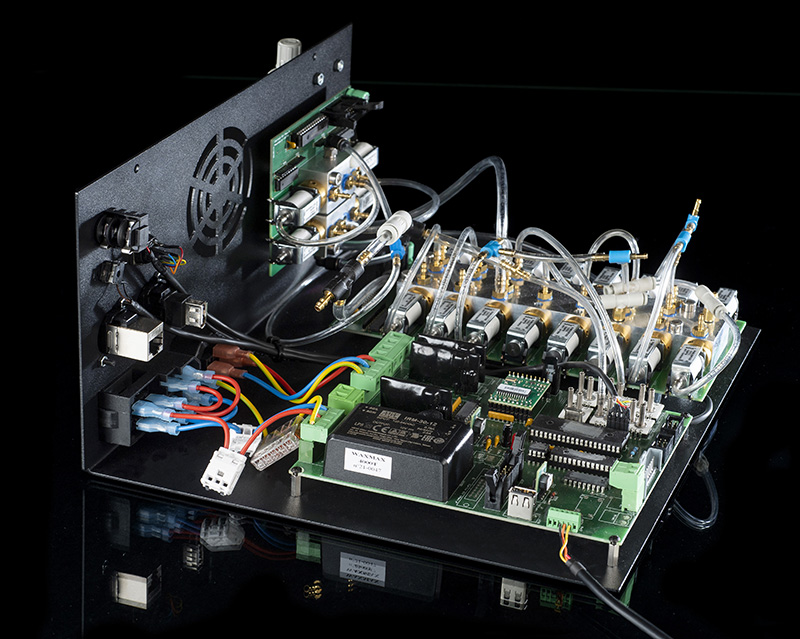

WAXMAX CONNECT, NETWORKING, OPTIMISATION AND PRODUCTIVITY

In addition to the injector, an external Waxmax Connect module is available. It is designed to support communication between several injectors: the same information is shared in a single database. The injection data of all connected machines is saved for subsequent statistical analysis.

- All machines in a workshop have access to the same saved settings: knowledge of the output per machine and per mould, analysis of rejects to optimise the use of moulds.

ENERGY AND ECONOMY

Designed with a programmer, the Waxmax Connect module enables programming the start-up and stand-by functions of the machines.

- Low energy consumption: machines ready to run upon arrival of operators.

COMPACT, FOR BETTER WORKING COMFORT

The Waxmax 5000 injector is the most compact professional device on the market: the injector unit, excluding the press, occupies only 31 x 31 cm of the workspace!

- Suitable for small spaces: space-efficient, saving up room for the necessary moulds and tools.

TOUCH INTERFACE, ADJUSTABLE SCREEN: TIME SAVING!

A software interface designed in collaboration with users offers quick and easy access to the menus. Pictograms simplify understanding of functions, while photos of the pieces can be added.

- Shorter adaptation time, ultra-fast production mode, easy updates, accelerated search for settings by piece.

DESIGNED AND MADE IN FRANCE: ROBUST AND UPGRADABLE

The injector’s metal structure and the modular design offer rock-solid reliability. The wired connections between the various components enable secure and optimised data transmission.

- Machine with great run-time, easy and quick to maintain, spare parts available from local dealer, upgradable device.

OPTIMISED VACUUM PUMP FOR INJECTOR

A specific vacuum pump, totally independent from the customer’s network, helps to optimise the vacuum of the mould ready for injection.

- The injection is perfect and precise, wax is evenly distributed in the mould whatever the shape of the pieces.

TANK: LARGE CAPACITY AND OUTPUT

A 9 litre tank can hold a large quantity of wax, injected directly into the mould without an intermediate chamber limiting the injection volume.

- The machine caters to moulds of all sizes, even the largest ones: the tank is filled up at fewer intervals to optimise output.

DEBUBBLING AND QUALITY

A debubbling system enables the wax to be degassed under pressure in order to prevent the appearance of air microbubbles during injections.

- Constant injection quality over time: perfect surface finish of the pieces.

EASY AND SECURE OPENING

The main tank is equipped with an easy-to-handle and secure lid.

- Dual benefits: safe to operate, wax easy and quick to fill up.

ULTRA-PRECISE AND CONSTANT INJECTION

Multiple settings allow determining the right configuration for each piece.

Temperature settings independent from the wax dropping point ensure repeatable injections regardless of the type and batch of wax used.

- Device suitable for all types of pieces and waxes: constant injection quality from one device to another and from one wax batch to another throughout the year.

OUTPUT AND OPTIMISATION

The device is designed for optimum output, even without a conveyor machine: 5 pieces/min.

CENTRAL CYLINDER

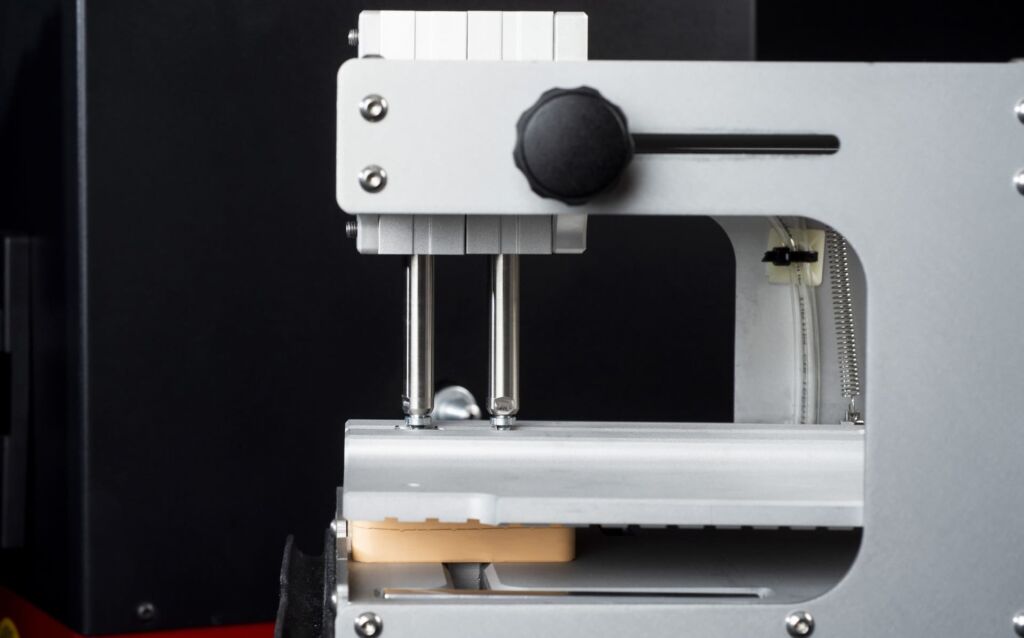

For non-planar moulds, a double cylinder technology allows the press to perfectly hold all types of moulds, even imperfect ones.

- Compensates for non-planar moulds.

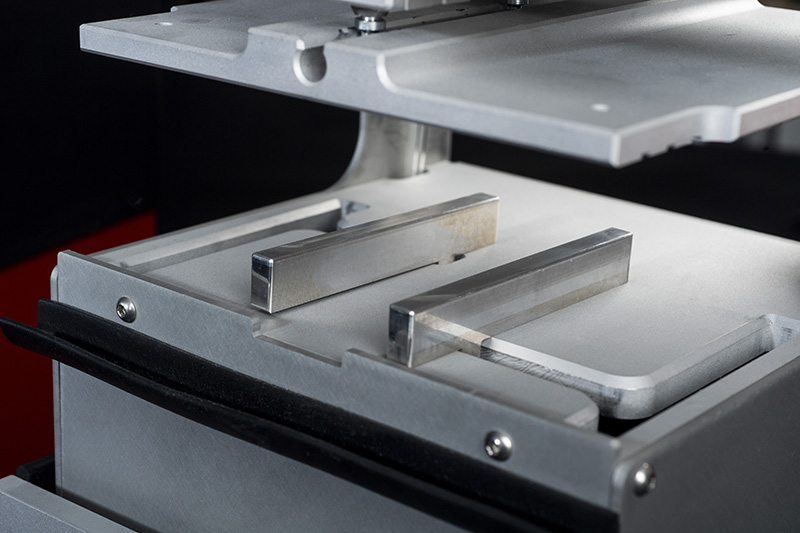

CYLINDERS AND POSITIONING

Precise adjustment of the clamping force regardless of mould size.

- Avoids parting lines, support all mould sizes

INJECTION PLATEN AND PRECISE ADJUSTMENT

Mould size or off-centre injection cone: machine self-adjusts even if the mould is not precisely facing the nozzle.

- Precise mould readjustment if the injection hole is off-centre, wide choice of mould sizes.

PRESS: MODULAR AND ADAPTABLE

Press separated from the injector body to allow front or side injection of the moulds.

- Device can be configured and adapted to the user’s requirements: Adapted to the user’s wishes and not the other way round. A standard injector can be bought and then completed with the convenient press.

- Price and configuration tailored to the user’s actual needs.

EASY TO REMOVE FOR AN INJECTION OF ANY SIZE

The press can easily be removed to provide more space for injection of larger moulds. The injector’s modular design allows all mould sizes to be covered by simply changing the injection press or enables manual injections.

- Optimises injection of all types and sizes of moulds. The standard press covers nearly all market requirements.

INTERCHANGEABLE INJECTION NOZZLES : HIGH QUALITY AND ADAPTABILITY

Equipped with an interchangeable injection nozzle adaptable to all kinds of moulds, for a perfect sealing between the injector and the mould cavity.

- High quality injection regardless of mould manufacturing technique. Machine adaptable to all moulds, including those designed for other injectors.

LATERAL CLAMPING: QUALITY AND PRECISION

The mould to be injected is held on each side to be perfectly positioned, without deformation, in front of the injection nozzle.

- Lower scrap rate. Injection quality and precision, extensive choice of mould sizes.

Characteristics

OPTION

Option

Environment |

|

|---|---|

| Operating temperature | 15°C -> 40°C |

| Humidity | 40% -> 80% non-condensing |

| Altitude | 0 m -> 1 000 m |

|

|

| With standard press | L 560 x l 310 x h 560 mm |

| Without press | L 310 x l 310 x h 560 mm |

|

|

| Injector only | 28 Kg |

| With standard press | 38.5 Kg |

| With lateral clamp press | 40 Kg |

|

|

| Standard press | Min L 47 x l 30 x h 16 mm |

| Max L 117 x I 170 x h 60 mm | |

| Lateral clamp press | Min L 35 x I 170 x h 16 mm |

| Max L 145 x I 170 x h 16 mm | |

|

|

| Capacity | 9 litres |

| Total capacity (with wax) | 6 litres |

|

|

| Voltage | 230 VAC – 50/60Hz with earth |

| Maximum current | Without vacuum pump 3.15Amp @230V |

| With vacuum pump 4.15Amp @230V | |

| Power | Without vacuum pump 736W |

| With vacuum pump 960W | |

|

|

| Screen | LCD 10.1’’ Multitouch Capacitive |

| Software | Android 9.0 |

| Connectivity | USB host, Ethernet |

|

|

| Internal Memory | 100 memory slots |

| Shortcuts | 5 slots |

| Languages | French – English |

|

|

| Temperature | Tank 60°C -> 90°C |

| Injector 60°C -> 90°C | |

| Pressure | Tank 0,1 b -> 2,4 b |

| Press 0,1 b -> 4 b | |

| Advance 0,1 b -> 1,5 b | |

| Lateral clamping up to 4.5 bar (manual setting) | |

| Time | Vacuum up to 60 sec |

| Injection up to 60 sec | |

| Cooling up to 60 sec | |

|

|

| Pneumatic | Flexible connection Ø 4 x 6 mm – Pmax 4,5 bar |

| Electrical | EU plug type E (other models on request) |

|

|

| Accessory | RFID Reader |